charpy test is not a type of impact test.|what is the charpy test : maker Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . web9 de ago. de 2023 · Programação. Filmes. Hoje é Um Novo Dia. Institucional. Globoplay. Criança Esperança. Perguntas Frequentes. grupo globo. Assista à TV Globo de graça e de qualquer lugar.

{plog:ftitle_list}

WEBO e-Fomento é um portal que permite o acesso aos serviços e informações do CNPq, incluindo a Plataforma Integrada Carlos Chagas, que reúne os dados dos .

charpy impact tester locator

Once the Charpy impact tester completes the test, the results are typically presented as the amount of energy absorbed during the fracture, measured in joules. These Charpy impact test results help manufacturers and engineers determine whether the material is suitable for its .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa.

Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its .Both Charpy and Izod impact testing are popular methods of determining the impact strength or toughness, of a material. These tests measure the total amount of energy that a material can absorb. This energy absorption is .

charpy impact tester manufacturers

The Charpy V Notch (CVN) test is a basic method for defining toughness and, in this process, toughness is defined in “joules or ft lbs” at the “temperature of test”. There are other, more complex methods but the CVN test is cheap, is a good . Charpy and Izod tests (also known as “notch impact tests”, “notched impact tests” or “V-notch tests”) are two of the most commonly used impact testing methods. Charpy and Izod Automatic Impact Tests. Both .The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the . Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered. . affect the .

Charpy improved upon the pendulum-based approach first developed by S.B. Russell. He discovered that adding a notch into the sample helped improve the accuracy and sensitivity of the test. The Charpy Impact . History of the Charpy impact test. The history of Charpy V-notch impact testing dates back to the early 1900s when French engineer Georges Charpy developed a standardized method for testing the impact toughness .

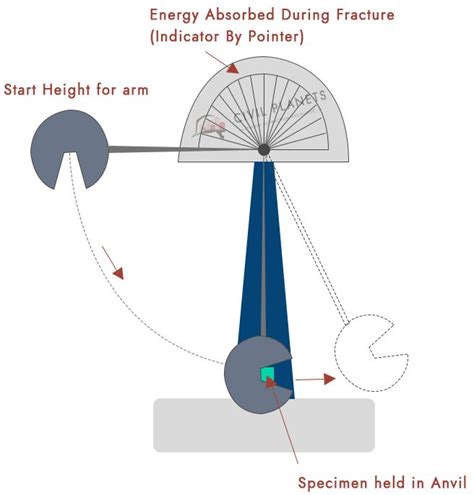

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface. The 3D Solutions Library operated by KEYENCE introduces examples of shape measurement problems and the latest solutions for various industries, .The value of energy absorbed is read directly from a dial on the machine. A typical impact testing machine is shown in Figure. 1. Figure 1. Schematic of a Typical Charpy Impact Testing Machine. In carrying out a test, the specimen is loaded into the anvil with a pair of special tongs that facilitate location of the specimen in the machine.The Charpy impact test is a widely known test famous for its accuracy in measuring metallic and plastic materials. SB Russell and George Charpy introduced this in the 20th century to measure the strength of the material. . In the Charpy test, you can expect two types of notches. One is the U-shaped notch, which is suitable for brittle .

Many notched bar impact tests of different designs and loading have been used to predict brittle fracture of ferritic steels. In the USA, the Charpy specimen has been standardized in ASTM E23 for impact three-point bend testing (ASTM E23 1999).Figure 1 illustrates a standard ASTM type A Charpy impact test specimen. The Charpy three-point bend specimen is more convenient . How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

What is an impact testing machine? An impact testing machine is used to determine the resistance of a material or component to a rapid load under varying temperature conditions. Depending on the material to be tested, the end-use application requirements, and the preferred type of test data, a choice is made between pendulum impact testers and .

1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energy The specimens generally used for performing the impact test are: charpy specimen and izod specimen, both specified by ASTM E23 standard. Of these two, the type of cp (proof body) charpy type is the most used without a doubt. It is so used that the impact test is sometimes called "charpy" (pronounced with stronger sound in Y). Charpy Test BodyA widely employed method for assessing weld toughness and impact resistance is the Charpy test, also known as the Charpy V-notch test. This article provides an in-depth exploration of the Charpy test, covering aspects such as the test machine, specimen preparation, temperature variations, test results, and the advantages of this evaluation .The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer.

1.1 - Pendulum Impact Test The most common configuration for pendulum impact test are Izod and Charpy ones. The scope of these impact test is to measure the answer of a standard test specimen to the pendulum-type impact load. The result is expressed in term of kinetic energy consumed by the pendulum in order to break the specimen. The energy A decade before an iceberg shattered the hull plates of the Titanic and half a century before a plague of brittle fractures started sinking Liberty ships during World War II, scientists in the United States and France had devised a . In 1905 another Frenchman, George Charpy, developed a pendulum-type impact testing equipment based on an idea by SB Russell. This testing equipment continues to be the most widely used equipment for the impact testing. . Charpy impact testing does not produce numbers that can be used for design purposes, but is widely used in specifications .

Figure 2-1: Geometry required for an ASTM standard Charpy impact test. 1 Type A is the geometry modified for our testing due to limitation in casting thickness in BMG alloys. 19 Figure 2-2: A schematic of a Charpy impact test. 2. Some materials, upon cooling below a critical temperature, will exhibit a rapid decreaseThe test is ideally performed on unnotched specimens with edgewise impact (1eU). Should the specimen not break during the test, any subsequent tests are performed with notched specimens. In this case, a comparison of the test results is not possible. If the notched specimen still does not break, the impact tensile method is used.

Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of the material.There are two main forms of impact test, the Izod and the Charpy test. . The Izod test is rarely used these days for weld testing having been replaced by the Charpy test and will not be discussed further in this article. The Charpy specimen may be used with one of three different types of notch, a 'keyhole', a 'U' and a 'V'. . The Charpy impact test is one of the most widely used techniques for evaluating the impact toughness of metallic materials. This test is based on measuring the energy absorbed by a material during fracture caused by a sudden impact, simulating real stress conditions that could cause a metal component to fracture.

Charpy Impact Test Specimen Dimensions. A Charpy test specimen, which is placed horizontally into the machine, is typically a 55 x 10 x 10mm (2.165" x 0.394" x 0.394") bar with a notch machined into one of the faces.To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :

what is the charpy test

Charpy Impact Test ISO 179. Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the kinetic energy needed to initiate fracture and continue the fracture until the specimen is broken. The Charpy test is used to determine the resistance capacity of metal (steel) specimens against the sudden impact of a pendulum that swung from a certain height. The Charpy impact is also known as the Charpy V-notch test because the specimen used in this test is cut at a certain depth in a ‘V’ [.]impact is applied to the face directly behind the notch using the blow from a swinging pendulum hammer. The impact testing machine calculates the energy absorbed, which can be converted to impact strength using the following equation: impact strength = energy absorbed area under the .

charpy v notch test

charpy v notch impact test

Strike the savings jackpot with MGM Detroit online coupons. 12 curated deals & promo codes from MGM Grand Detroit tested & verified by our team daily. Get deals from 5% .

charpy test is not a type of impact test.|what is the charpy test